PRODUCTION INDUSTRY OF WIRE AND CABLE, application

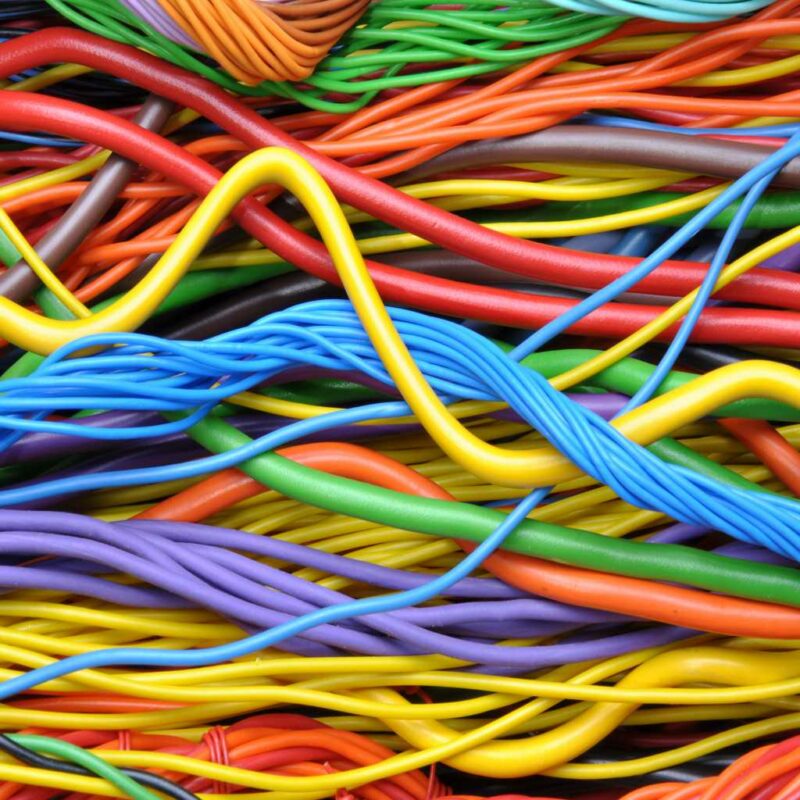

PRODUCTION INDUSTRY OF WIRE AND CABLE

Colors should have the following characteristics to meet the requirements of the electrical wire and cable industry:

1. We use special processes and formulas to design color masterbatch that meets the stringent cable and electric cable production requirements. The product has good quality, such as electrical compatibility, good dyeing properties, heat resistance, resistance to change and dispersion. We strive to meet the heat resistance and insulation effectiveness of electric wires and cables. The surface of the product is glossy, bright and has good weather resistance, providing high efficiency.

2. This color masterbatch series is developed in compliance with RoHS, REACH, halogen and other environmental laws and regulations. The color of the product can be customized according to customer requirements.

This masterbatch series is designed and developed for electric wires and cables. Color masterbatches use high quality and concentration pigments to make pigments. It is mixed at high speed with various additives and made into plastic granules by banbury mixer and processed by twin screw extruder. The product has good processing effect and is suitable for many types of extruder.

Application

Color masterbatch is suitable for PE, PVC, EVA, low-smoke and halogen-free materials, and other resins designed for electrical wires and cables The product is applied in the production of various types of wires and cables such as communication cables, data cables (network lines), electronic and automotive cables, including insulated wires and cables, insulated wires and cables.

Tiếng Việt

Tiếng Việt