As one of the most cost-effective material solutions, calcium carbonate filler is widely used in various applications, which include non-woven fabric. In this article, let’s discover amazing benefits of calcium carbonate filler in non woven and interesting usage tips to help you make full use of it.

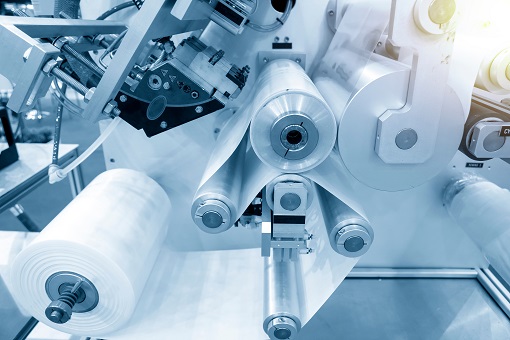

Being first introduced in the early 1930s, non woven fabric was initially considered as a cotton waste-utilizing method. Not until the first commercial production launched in the United States in 1942, the market for non-woven has witnessed tremendous growth.

What is non woven fabric?

Non woven fabric is a sheet or a web structure that is bonded together by entangling fiber or filaments (by perforating films) mechanically, thermally or chemically. Typically, it offers specific functions such as absorbency, liquid repellency, resilience, stretch, softness, strength, flame retardancy, washability, cushioning, thermal insulation, acoustic insulation and filtration. These properties are then mixed and matched to create specific fabrics that suit end products’ requirements.

Thanks to these outstanding properties, non woven fabric is widely used in several applications. Generally, they are divided into 4 main categories:

- Disposable nonwovens: this type of nonwovens are mostly made for single use products or reusable ones (such as dust cloths – which may be laundered and reused a few times).

- General applications: include personal hygiene products, such as diapers and sanitary napkins; medical products such as surgical gowns and drapes; surgical and industrial masks, bandages, wipes and towels; bibs and even costumes for special events.

- Durable nonwovens: widely used in both household goods and home furnishings, such as for draperies, furniture upholstery, mattress padding, towels, table cloths, blankets and carpet backing and clothing and apparel, such as for caps, linings, interlinings, interfacings and the reinforcement of other fabrics.

- Other industrial uses: such as filters, insulation, packing materials, roadbed stabilization sheeting or road-building materials, geo-textiles and roofing products.

Vital role of calcium carbonate filler in non woven

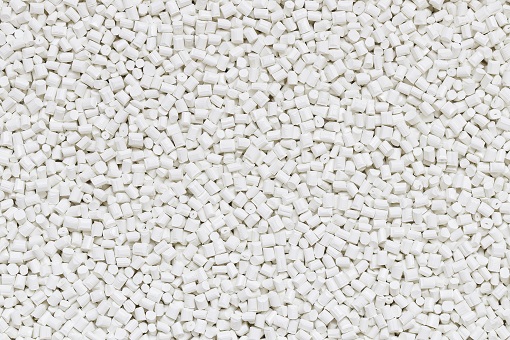

With a view to optimizing the production of non woven, calcium carbonate filler has been taken into use. Being made of calcium carbonate powder (CaCO3), plastic resins and other specific additives, calcium carbonate filler is one of the most effective material solutions to non woven manufacturing. The application of this material offers end-products several benefits:

Cost reduction

Containing CaCO3 powder, which is a reasonable substance compared to virgin resin, calcium carbonate filler helps manufacturers save a significant amount of material expenses. Thus, it lessens the dependence on fossil resin as well as minimizing the negative impacts of the global market on the manufacturers. Besides, the decrease of raw material price definitely gives them a leg up in a competitive market.

Properties enhancement

The introduction of calcium carbonate filler in non woven can improve matte, enhance opacity, increase strength, and provide a cotton-soft feel for comfort. As CaCO3 modifies the fiber, it also helps soften and give a more matte appearance to the fabric surface.

Specifically, the natural whiteness of CaCO3 limits the formation of yellowness on the fabric surface. Plus, by increasing the opacity in fibers, it also enhances the covering power of the web.

Furthermore, this material significantly improves the air filtration and oil absorption ability of the end products. It also disperses well in resins and incorporates easily during extrusion.

Productivity improvement

As CaCO3 is a good thermal conductive, it reduces processing temperature and shortens the products cycle, thus saving energy consumption as well as increasing productivity.

Environmental friendliness

Last but not least, an outstanding advantage of calcium carbonate filler is its environmental harmlessness. Compared to fossil resin, which releases a great amount of carbon footprint during its manufacturing process, the production of filler masterbatch is far more environmentally friendly. Also, it is an ideal alternative to non-renewable materials, thus opening up sustainable development for nonwoven manufacturers.

How to apply calcium carbonate filler in non woven effectively?

Normally, polypropylene (PP) calcium carbonate filler is applied in non woven fabric to attain the compatibility to the resin. To achieve the best result, there are certain factors that should be taken into consideration.

The thickness of the fabric

This factor determines the dosage rate of calcium carbonate filler that needs to be added into the combination. In particular, the recommended usage rate for thin fabric is from 5 to 20%, for medium fabric is 20-35% and it reaches up to 60% for thick fabric. In case an extremely good dispersion and stability are required, filler masterbatch is typically applied with a loading rate of 78-80% and melt flow index from 20-40g/10 min.

The melt flow index (MFI)

The melt flow index (MFI) is a measure of the ease of flow of the melt of a thermoplastic polymer at a certain temperature and loading rate. For non woven fabric, this index varies among different levels of fabric thickness. In which, the thinner fabric requires a higher MFI while a lower MFI is recommended for the thicker ones.

An important note for manufacturers is that any changes in the dosage rate of calcium carbonate filler in non woven products should be made gradually. Also, you need to consider carefully before making any adjustments to machine parameters.

Common problems in non woven manufacturing process: causes and solutions

Fiber drop

This phenomenon is normally caused by the following factors:

Stone powder is stuck in the die head of the extruder, which makes the yarn not run into a stream, thus resulting in uneven yarn output and yarn drop. To solve this problem, an easy way is to clean the extruder die and make sure you prevent its occurrence next time.

Filter mesh is clogged which leads to the uneven yarn pressure and yarn drop. By cleaning the filter net and figuring out what causes the mesh, manufacturers can come up with an appropriate solution.

Slow MFI of the calcium carbonate filler leads to the unstable flow. As mentioned above, MFI is a vital index that determines the efficiency of the manufacturing process. To fix this, manufacturers may need to make some adjustments to the extruder’s temperature. However, in the long run, it’s recommended to innovate the filler formulation for better MFI.

Machine parameters are not suitable for production materials. In this situation, the only way is to adjust machine parameters.

Fiber is too soft or too hard

When it comes to the mechanical properties of end products, the main cause lies in the formula of calcium carbonate filler in non woven fabric. A large amount of filler masterbatch may lead to the lack of stiffness of the fabric, while hard surfaces of end-products mainly result from the absence of some groups of additives.

Weak mechanical properties

The main causes of this problem may be the incompatibility between the type of calcium carbonate filler used in non woven or the oversized stone powder particle, which ends up with the poor bonding force of the fabric. Hence, manufacturers should recheck the filler masterbatch formula to ensure that it suits their end products best.

Tiếng Việt

Tiếng Việt