NEWS

4 most common plastic filler materials in plastic industry

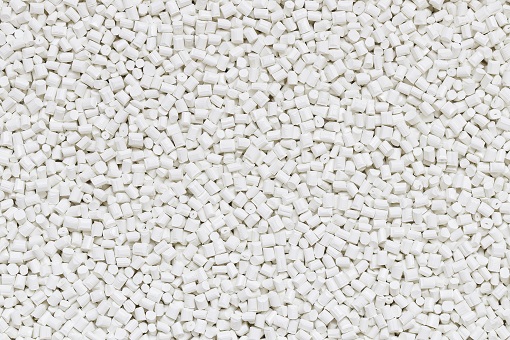

There is no denying that plastic filler materials are one of the most essential factors in retaining cost-effectiveness for plastic firms. Let’s take a look at 4 most common plastic filler materials in the plastic industry to better acknowledge the benefits of these magical materials.

Plastic filler materials are known as one of the key factors leading to the revolution of the plastic industry. The volume of plastic filler consumption reached approximately 33 billion tons in 2016. Countries which record the largest number of plastic beads materials exported include Asian countries such as China, Japan, Korea,…, followed by North America and Europe.

The use of plastic filler materials have brought various benefits to plastic firms, in which the most important is cost reduction and mechanical properties enhancement.

1. What are plastic filler materials?

For a long time, primary plastic has been seen as the only way for many manufacturers who wish to manufacture plastic products. At that time, plastic production was extremely unstable and risky due to the uncertainty of oil, which is the main source of all types of plastic worldwide. As such, for a large number of companies, especially those who depend completely on foreign market, plastic production has never been an easy task, as they are usually put into a struggling situation when primary plastic’s price gets higher or delivery is late as a consequence of the unexpected.

That’s the reason why the plastic filler materials are born. Technically, they are particles added to plastic production to cut cost as well as supporting in enhancing some properties of end-products. Plastic filler materials are divided into two groups:

- The inorganic (also known as mineral) fillers such as calcium carbonate (limestone), magnesium silicates (talc), calcium sulfate, mica, calcium silicate, barium sulfate and kaolin (China clay).

- The organic plastic fillers such as tree bark flour, nut flours, chicken feathers, and rice hulls.

Normally, the inorganic filler materials are more prefered in industrial production as their simple molecular composition makes them more easily to be processed. Therefore, in this article, we would like to go deeply into the inorganic ones.

2. The most commonly used plastic filler materials

As mentioned, there is a wide variety of plastic filler materials and their uses completely depend on the characteristics of end-products as well as the standard requirements. These listed below are the top 4 most widely used in the plastic industry.

Calcium carbonate (CaCO3)

Calcium carbonate is a substance which is most commonly found in the form of rocks or limestone. It is also the main component of eggshells, snail shells, seashells and pearls. In the plastic industry, calcium carbonate is also widely used as one of the plastic filler materials. It improves mechanical properties (tensile strength and elongation) and electrical properties (volume resistivity) when being added to PVC. Polypropylene is another resin that uses calcium carbonate at the proportion of 20 – 40% as it strengthens the rigidity – an important requirement when plastic is exposed to high temperature. Most importantly, this matter helps significantly decrease the overall production cost, which often accounts for up to 60% of product’s price. Compared to primary plastic, CaCO3 is more reasonable and less fluctuating, thus degrading the uncertainty for the business.

Magnesium silicates (talc)

Talc is a clay mineral, composed of hydrated magnesium silicate and made of three main components including magie, silic and oxi. In nature, talc is a common metamorphic mineral in metamorphic belts that contain ultramafic rocks, such as soapstone (a high-talc rock), and within whiteschist and blueschist metamorphic terranes. It is widely used in the plastic industry as one of the effective plastic filler materials to enhance durability, thermal resistance, anti UV and anti aging ability. The combination between talc and plastic resins creates talc filler masterbatch, which is widely prefered thanks to its mechanical properties enhancement and processability as it requires no changes in the manufacturing equipment, thus saving a large amount of expense for plastic firms.

Besides, talc can also be added into compounds (tailor-made materials to serve for a specific plastic product) to enhance end-products properties such as rigidity, modulus bending, flexural strength as well as decreasing the level of shrinkage, warping and improving the conductivity and surface rigidity.

Sodium sulfate (NaSO4)

Sodium sulfate is another well-known substance which is widely used as a plastic filler. Sodium sulfate’s fomular is NaSO4 and mostly found in the form of decahydrate (known as mirabilite mineral or Glauber’s salt). NaSO4 is commonly known for its high solubility in water and it rises more than tenfold between 0 °C to 32.384 °C. One outstanding advantage of sodium sulfate is its transparency (more clear than calcium carbonate) and its reasonable price (cheaper than barium sulfate). Therefore, sodium sulfate is widely used as one of the plastic filler materials.

The use of sodium sulfate significantly improves the transparency and glossiness of plastic products. Also, it reinforces end-products mechanical properties with excellent dispersion, high tenacity and strong stability. Furthermore, sodium sulfate is highly recommended thanks to its eco-friendly components, which barely pose any threats on our environment.

Barium sulfate (BaSO4)

Barium sulfate is an inorganic compound that is odorless and insoluble in water. It is commonly used as a plastic filler to increase the density of the polymer in vibrational mass damping applications. In polypropylene and polystyrene plastics, it is commonly used as a filler with a proportion of 70%.

However, one disadvantage of barium sulfate is the relatively high price compared to other plastic filler materials. The more transparency required, the larger proportion of BaSO4 needed, thus costing plastic firms a greater amount of production expense. That more or less raises hesitation from customers’ view as they are looking for an alternative solution for primary plastic to address the cost’s problem, not to get another burden.

3. Which plastic filler materials to choose?

As such, there is a large number of plastic filler material for plastic firms to use. However, the challenging part is how to choose a suitable one for your companies. These criteria below may simplify your decision making process:

What are your end-products? This should be the first priority for any firms who wish for a plastic filler. What are your products used for? What are their standard requirements? Which mechanical properties do you expect? That information definitely gives you a clue on which should be the right plastic filler material.

Are you on a budget? Of course, you are searching for plastic fillers with a view to saving on production cost. However, even the price of plastic fillers varies from the lowest like calcium carbonate to the highest like barium sulfate. Therefore, positioning a range of acceptable prices is necessary.

Quality and reliability should never be underestimated. A famous manufacturer who owns a good reputation is undoubtedly more trustworthy than an unknown one, especially those experienced in the market can give you valuable advices on appropriate products.

Tiếng Việt

Tiếng Việt