The packaging is the biggest market for additives.

The output of plastic packaging depends strongly on the population, people’s average income, and expenditure.

We need plastic packaging mostly for the food and beverage industry. Therefore, the increase in the population and the average income will have a positive effect on the demands of plastic packaging as well as additives.

Packaging industry

Foreign market

Asia has the rapid growth in the consumption of plastic packaging.

The first reason is that Asia has the highest and most developing population rate. Researchers forecast that Asia is going to reach 4,3 billion people in 2022. Moreover, the population growth rate and GDP growth rate are “gold rate” and desirable.

Besides, Europe and North America consume plastic packaging a lot. While those 2 regions have a quite low population density, they have a good source of income and their consumption habits of plastic packaging were established a long time ago (since 1950).

Flexible packaging makes up 59% of the total consumption of plastic packaging.

Flexible packaging is made from PE and PP resins by blow molding. The consumption of flexible packaging and bottle packaging is forecasted to decrease a little bit due to the increase in people’s awareness of the environment.

Food packaging and bottle packaging made up for 93% in 2,400 billion of packaging products in 2018. The demand for food packaging will reach 1,788 billion products in 2022.

Asia is the main and most potential market for the plastic packaging industry.

As I said before, Asia has the gold growth rate of population and average income.

Another reason is that many developed countries are moving towards “green life”, minimizing the use of single-use plastic products.

Việt Nam

The development in the non-alcohol beverage market will drive the plastic packing industry in a new chapter.

The demand for plastic packaging products mainly depends on the growth of food production, the beverage industry, and household income and expenditure in general.

According to BMI, household spending will be about VND 3.3 million billion in 2019 VND and 4.7 million billion VND in 2022. Of which, spending on food and non-alcoholic beverages will still account for a large proportion, about 20% of total household expenditure.

The growth of food and non-alcoholic beverages is expected to grow by 11.8% and 12% per year, respectively, from 2019 to 2022. This is the main driving force for the growth of food processing and beverage industries.

Main Additives used

Materials/Resins

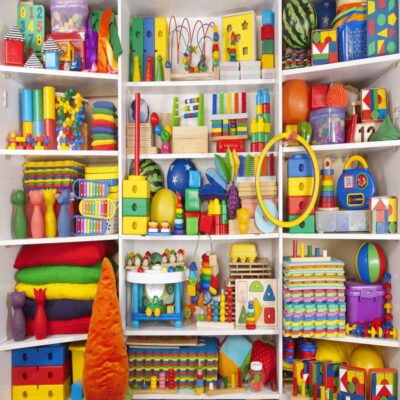

The 5 most popular additives used in the packaging industry are anti-blocking and slip agents, anti-fogging agents, the usual heat and light stabilizers, and pigments.

Oxygen scavengers are also getting popular in food packaging.

PE is the dominant packaging polymer, it is used in very high-volume shopping bags, rubbish sacks, and food packaging. HDPE is the most essential, especially in Europe.

PP is used more in the specialized role of industrial goods.

Polyethylene naphthenate is being promoted in the form of thin, flexible film with good barrier properties.

Specific additives for packaging industries

Social habits change, people’s expenditure habits change. The increasing popularity of hanging out with premade meals and microwaveable containers leads to a remarkable increase in using food packaging; therefore, increasing the use of additives.

The technology to premade and packaged food requires special additives.

Plastic bottles and containers have undergone considerable changes in recent years due to increased interest in barrier layers.

Consumers also like bottles to have a wide mouth. PVC has been defeated as a bottle material by PET.

Adding an impact modifier creates a favorable condition for PET to gain competitive advantages over polycarbonate in manufacturing larger bottle sizes.

Moreover, PE clarifying additives allows you to produce cheaper and cleaner packaging.

Anti-fogging agents are used in flexible PVC food wrapping. UV absorbers used in transparent bottles to protect the contents and the polymer.

People are considering to stop using single-use plastic in many packaging applications. Due to litter issues, the fast-food industry is criticized a lot. Several countries have banned single-trip shopping bags.

Non-woven and multi-trip packages are trendy.

Tiếng Việt

Tiếng Việt