NEWS

Bullet-proof is actually made of plastic

On 27/2/2019, Hanoi hosted the summit between two of the world’s most infamous leaders: President Donald Trump of the USA and president Kim Jong Un of North Korea. Even though the visit of President Kim, as normally, was shrouded by mystery, there is one image that takes the world by storm.

This green train is entirely bullet-proofing, it is Kim Jong Un’s favorite means of transportation and carries the symbol of the North Korea leader.

In light of this bizarre event, this article would address a fact only military specialists may know: bulletproof vest and glass, as we often see in movies and television nowadays, all have plastic as one of the chief components.

The history of bullet-proof vest

Throughout the medieval and feudal eras, protection suit for combat soldiers were associated with the famous term “amour”. For centuries, soldier stormed into the battlefield with mail armor, a costume consists of iron, steel or brass chains. In many regions like China or Japan, people developed scale armor, with materials taken from animal scale, bone or hone to make leather and metal clad.

The arrival of the World War I had triggered severe changes and revolution in the use of weapon. Gunfire erupted the battles and experiments were called to invent a modern armor which can challenge of force of gun. Reinforced steel plate would also limit soldier’s movement and impede their arms. Several models of gunfire-proof were introduced but in the end, none really made a significant effect.

The plastic revolution of the 1940s marked a turning point in the history of weapon technology. Military scientists invented the first models of the modern bullet-proof vest, made of ballistic nylon fused with plates of fiber-glass, titanium, steel and ceramic. They bore the strength of steel and the resilience, lightweight of plastic. Due to such convenience, the vests were widely used by law enforcers and military personnel.

In 1965, Du Pont chemist Stephanie Kwolek invented the Kevlar, the most common bullet-proof suit until today. Instead of ballistic nylon, Kwolek turned to poly-para-phenylene terephthalamide, a type of polymer that can be transformed into aramid fiber and sewed into cloth. Since then, Kevlar suit has been the standard and traditional bullet-proof vest.

A traditional Kevlar suit, thin and light-weight

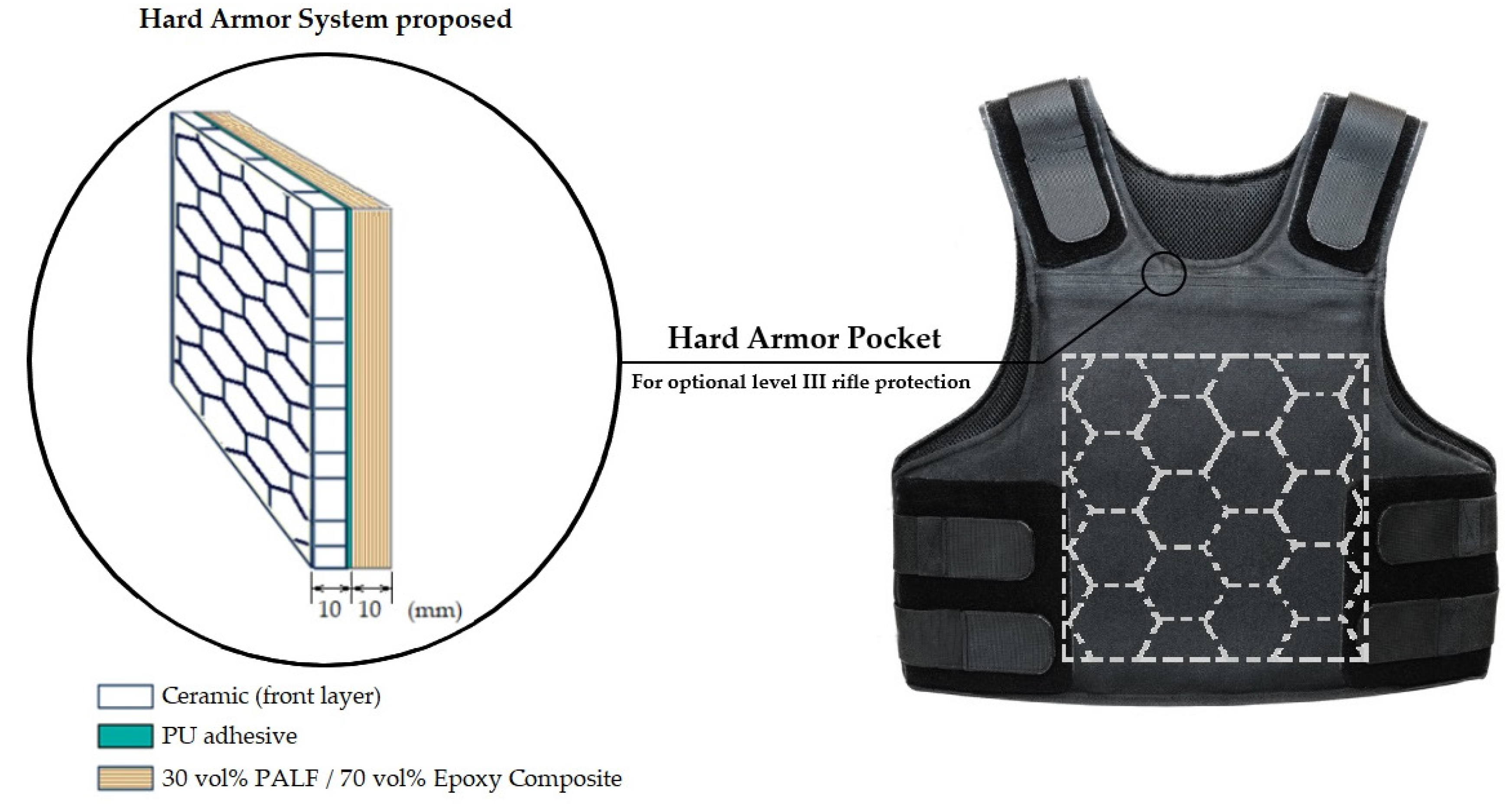

Nowadays, bullet-proof vest is made from a sheet of advanced plastic polymer, with layers of Kevlar or other material like Spectra Shield, coated and bounded by resins. In extreme situation, metal plates can be inserted between the fabric to protect the most vulnerable part such as chest or upper back.

Bullet-proof glass: A sandwich of glass and plastic

A normal piece of glass would shatter if hit by a bullet simply because glass is inflexible. It cannot bend or absorb heat and energy. The science behind bullet-proof glass is simple to demonstrate: they are made from layers of glasses sandwiched with interlayers of plastic. The layers are often designed to maintain their thin width, but they are still twice heavier than an ordinary glass panel of the same size.

The mechanism of bullet-proof glass (Source: Total Security Solution)

When the bullet hit the glass, its energy will be spread and absorbed through the layers of glasses and plastic and quickly dries out. At this point, the glass layers will break apart, but it’s the plastic panel that hold them together. Therefore, when attacked by gunfire, bullet-proof glass will crack but not shatter, since only the glass panes are broken but the plastic remains.

Tiếng Việt

Tiếng Việt