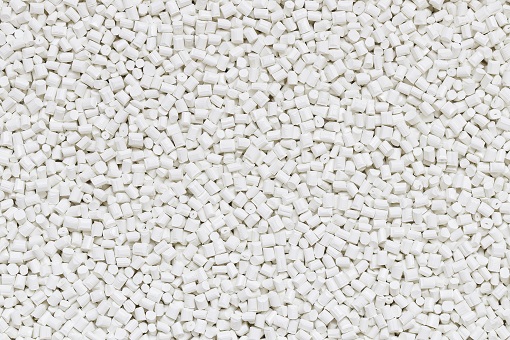

PPA Masterbatch is designed to enhance extrusion ability of plastics which leads to improve productivity and quality. Using PPA Masterbatch offers plastic producers many benefits such as: increasing output, reducing production costs, operating pressures and improving surface smoothness.

Advantages

- Reduces or eliminates die build-up

- Reduced interfacial instability in multilayer films

- Reduced gel formation

- Ideal for use in high viscosity, high molecular weight polyolefins

- Excellent thermal stability for high-temp. processing

- Lowers apparent melt viscosity

Applications

Blowing film: it helps eliminate melt fracture on the surface to make the surface smooth and beautiful.

Fiber extrusion, spinning for making mesh, weaving: it helps eliminate the falling phenomenon at the extruder, save production time, save cleaning costs.

Plastic pipe extrusion: it helps eliminate roughness caused by die-swell phenomenon, smoothing surface, reducing friction, and extruding capacity.

Extrude power cables, eliminate surface roughness and Die BuildUp, increase speed and input capacity for production lines.

+ Phone: 0251 351 4444

+ Email: cs@masterbatchvn.com

+ Website: www.masterbatchvn.com

Related products

ADDITIVES

ADDITIVES

ADDITIVES

ADDITIVES

ADDITIVES

ADDITIVES

ADDITIVES

ADDITIVES

ADDITIVES

Tiếng Việt

Tiếng Việt