Anti-Block Masterbatch, specially formulated to give faster migration & better open ability.

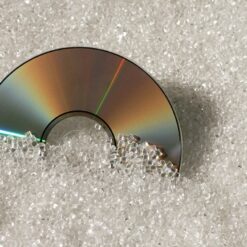

The processing of plastics films will be disturbed by a high Coefficient of Friction. This tendency to adhere to metal surfaces and to other film surfaces will be a limiting factor for high speed processing applications as packaging, handling of films, etc…

Anti-Block Masterbatch are added to reduce the surface coefficient of friction of polymers and are used to enhance either processing or end applications. This in turn enables faster winding and unwinding of films and prevents cracking of sheets during cutting or of thermoformed parts during denesting. Further benefits are excellent sealability and weldability.

Anti-Block Masterbatch have a low compatibility with the polymer which allow migration to the film surface. A good control of the compatibility controls the migration speed and thus the speed of acting performance can be engineered.

Please speak to our Sales representatives for your specific requirements. We will be more than happy to cater to your needs.

Applications

Blown film

Cast Film

BOPP

BOPET

Sheet extrusion

Profile Extrusion

Blow Moulding

Injection Moulding

+ Phone: 0251 351 4444

+ Email: cs@masterbatchvn.com

+ Website: www.masterbatchvn.com

Related products

ADDITIVES

ADDITIVES

ADDITIVES

ADDITIVES

ADDITIVES

ADDITIVES

ADDITIVES

ADDITIVES

ADDITIVES

Tiếng Việt

Tiếng Việt